Learn about adhesion testing, when to use this test type and the typical probes and attachments for use on a Texture Analyser.

An adhesion test measures the force required to separate two surfaces that have been brought into contact under controlled conditions. It quantifies a product’s adhesive strength, tack, and cohesiveness, helping manufacturers understand how strongly a product sticks to another surface or itself.

Adhesion testing is essential for both desired stickiness (e.g. adhesives, tapes, confectionery) and unwanted tack (e.g. doughs or coatings that cause production issues).

For any typical texture/physical property measurement test the force to pull away from a sample after it has been deformed would appear in the negative region of the curve.

In Stable Micro Systems’ Exponent Connect software, a dedicated Adhesive Test allows users to define the approach speed and contact force that a probe presses onto a sample for a specified dwell time to form a consistent bond before pulling away at a Withdrawal speed to a chosen distance, while recording force vs. distance/time.

This unique controlled adhesion mode ensures repeatable adhesion measurements across a wide range of materials and surfaces.

A simple tack test briefly brings an adhesive into controlled contact with a probe or substrate under a defined force and time, then measures the peak force (and/or work) needed to separate-this captures the instant stickiness a user feels on first touch.

A basic peel test bonds a tape/film/laminate to a substrate, then pulls it back at a fixed angle (commonly 90° or 180°) and speed while recording the steady peel force, giving a clear measure of bond strength during removal in a way that mimics real use.

Adhesion testing provides both quantitative and qualitative information about the sample’s stickiness, flexibility, and failure behaviour:

Single or multiple parameters such as peak force, peel forces, elongation at break, tailing distance and work of adhesion can be collected from the graph. Understanding these parameters allows direct comparison between samples or production batches.

To learn more about how these properties are measured, visit our Textural Properties page.

A typical adhesion test curve consists of:

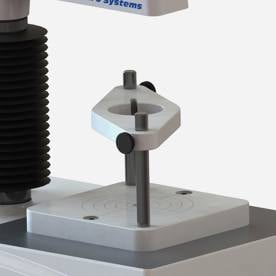

The choice of probe geometry and holding fixture is crucial for generating reproducible adhesion data. Stable Micro Systems offers a broad range of fixtures for different sample types and adhesion mechanisms.

|

Probe type |

Typical application |

Notes |

|

Cylindrical Probe / Platen |

General-purpose stickiness or surface tack testing |

Versatile option for tack; gives a defined contact area for routine comparisons but requires flat sample surface. |

|

Spherical Probe |

Adhesion of thin tapes or uneven surfaces |

Rounded tip reduces stress concentrations and provides consistent surface contact area for thin samples. |

|

Mucoadhesion Rig |

Medical or pharmaceutical bioadhesive studies |

Uses biologically relevant substrates to measure true mucoadhesive performance. |

|

Nail Polish Adhesion Rig |

Coating adherence on solid substrates |

Standardised substrate and pull-off geometry for coating bond strength. |

|

Dough Stickiness Systems (Warburtons, Chen–Hoseney) |

Measures dough surface tack and stickiness |

Industry-style imitative tests; strict control of dough prep and timing is essential. |

|

Pasta Firmness / Stickiness Rig |

Evaluates cooked pasta tack and cohesion |

Simulates serving/handling forces; keep cook time and temperature consistent. |

| Attachment | Purpose | Notes |

| 90° or 180° Peel Rig | Peel strength of tapes, films, and laminates | Fixed-angle peel for standardised, comparable peel-force results. |

| Universal Peel Rig | Adjustable for various peel angles | Lets you match real-world peel geometry by setting custom angles. |

| Large Peel Strength Rig | For high-strength adhesive tapes or laminates | Reinforced setup for higher loads and wider/thicker adhesive products. |

| Flexible Substrate Clamp | Holds thin films or flexible materials securely | Prevents slipping or tearing of delicate substrates during peel/tensile tests. |

| Adhesive Loop Test System | Tack loops and adhesive tapes | Measures tack via loop contact/separation using a repeatable method. |

| Tape Unwinding Rig | Quantifies unwind force in adhesive rolls | Simulates roll dispensing; keep unwind speed and roll alignment consistent. |

|

Rig |

Application |

|

Adhesive Indexing System (ALIS) with/without Multi-head Indexing Probe |

Enables multiple sequential peel/tack tests at different speeds |

Standard probes come in Delrin, stainless steel or aluminium. Bespoke geometries or materials can be produced to customer specification for specialised tests.

|

Industry |

Example applications |

Typical probe / attachment |

|

Food |

Sticky confectionery, mozzarella stringiness, dough stickiness |

Cylindrical or Dough Stickiness Rig |

|

Cosmetics / Personal Care |

Cream tack, lipstick adhesion, nail polish removal force |

Spherical Probe, Nail Polish Rig |

|

Pharmaceuticals / Medical Devices |

Mucoadhesion, gel tack, patch peel strength |

Mucoadhesion Rig, Peel Fixture |

|

Adhesives and Packaging |

Peel strength, tape unwinding, seal separation |

90° / 180° Peel Rigs, Adhesive Loop System |

|

Industrial / Coatings |

Paint or laminate adhesion, residual tack |

Universal Peel Rig or Craft Knife Probe |

To prevent base movement.

Ensure measurement within correct force range.

Adhesive Test configuration with 2000pps high speed data acquisition for the collection of detailed data during short dramatic tests.

For the testing of temperature sensitive samples.

It measures the force required to separate two surfaces, providing data on stickiness, work of adhesion, and stringiness.

Adhesive behaviour can be either a critical quality attribute or a problematic property, depending on the product. Measuring adhesion helps manufacturers:

Stickiness measures external surface adhesion; cohesiveness measures the internal strength of the material before separation.

Adhesion events occur rapidly; using a high acquisition rate (e.g., 2000 points per second) ensures accurate peak and curve detail.