Measuring the Volume, Density and Dimensions of Materials and Products

The Volscan Profiler provides the most comprehensive range of dimensionally-based parameters.

Density plays an important role in the interplay between mass and volume.

In the simplest terms, density is the mass of an object divided by its volume (g/cm³). Determining mass is very straightforward by way of a balance. However, determining volume (especially of an irregular shape) can present a challenge.

The volume of homogeneous solids with well-defined geometry can be readily calculated from their dimensions. However, most solids consist of heterogeneous combinations of particles with varying sizes and shapes. In such cases, volumes are most accurately measured by fluid displacement, according to the Archimedes principle.

Why measure Volume, Density or Product Dimensions?

The measurement of density is necessary in the manufacture of many of today’s products. It is an extremely valuable and reliable tool to characterise the structure and quality of solid materials quickly and routinely, such as catalysts, ceramics, foams, minerals, metal powders, soils, cements, pharmaceuticals, and many more. Density measurements guide the formulation process and influence the overall quality of manufactured products.

It is often beneficial, for performance or cost saving reasons, to reduce the weight of products whilst maintaining the overall physical size of the product. In fact, manufacturers often attempt to develop materials that are partially porous but still fulfil their technical function. In such products as home insulating materials, the presence of closed air bubbles is desirable. Automobile and furnace filters, on the other hand, require an open cellular structure. However, in other products, such as ceramics and laminate structures, prevention of porosity is crucial to their structural integrity.

When combined with other information, a material’s density can indicate possible causes of alterations to product characteristics. A change in density can be the result of an altered material composition or the presence of a defect (such as a void in a casting). This can help with quality control; for example, in aluminium foundries, the purity of a melt can be determined by looking at the relative densities of a part that has formed under air pressure and a part that has formed under a low pressure (such as 80 mbar).

The density of porous materials is affected by the quantity and size of pores. The porosity affects other material qualities, so its accurate measurement is very important. For example, the frost resistance of roof tiles or the properties of wall materials such as concrete are affected by porosity, and in turn, density.

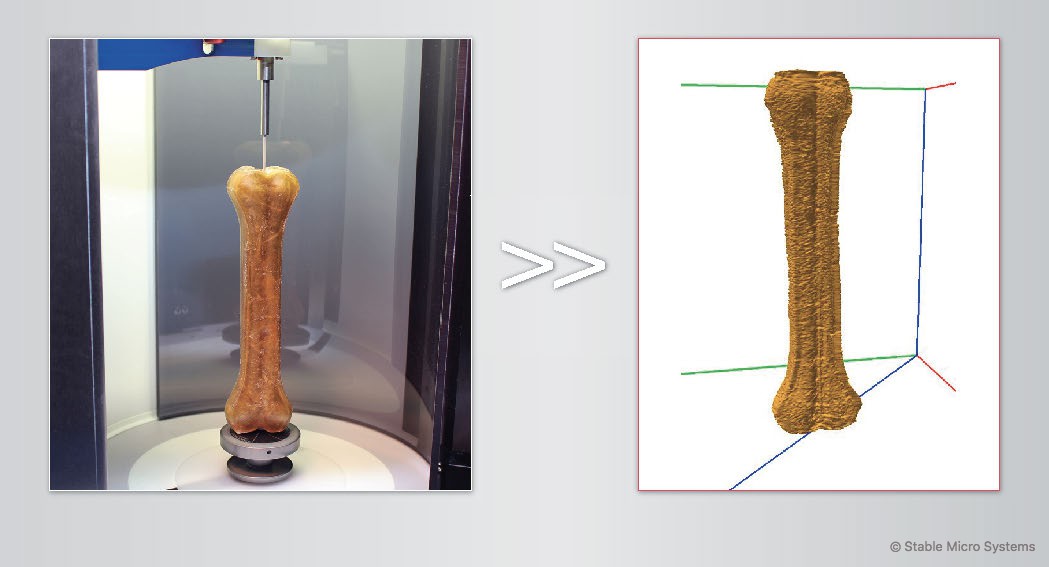

If you’ve designed a product in a CAD package and then you 3D print it, one concern will be whether what has been printed is what you designed. In many cases you’ll need your printed object to be dimensionally accurate and iterations of printing your design are almost inevitable to adjust the printing settings to obtain a product that is dimensionally accurate. And you’ll need a means of quickly and accurately measuring these dimensions.

Why measure Volume, Density and Product Dimensions using a Volscan Profiler?

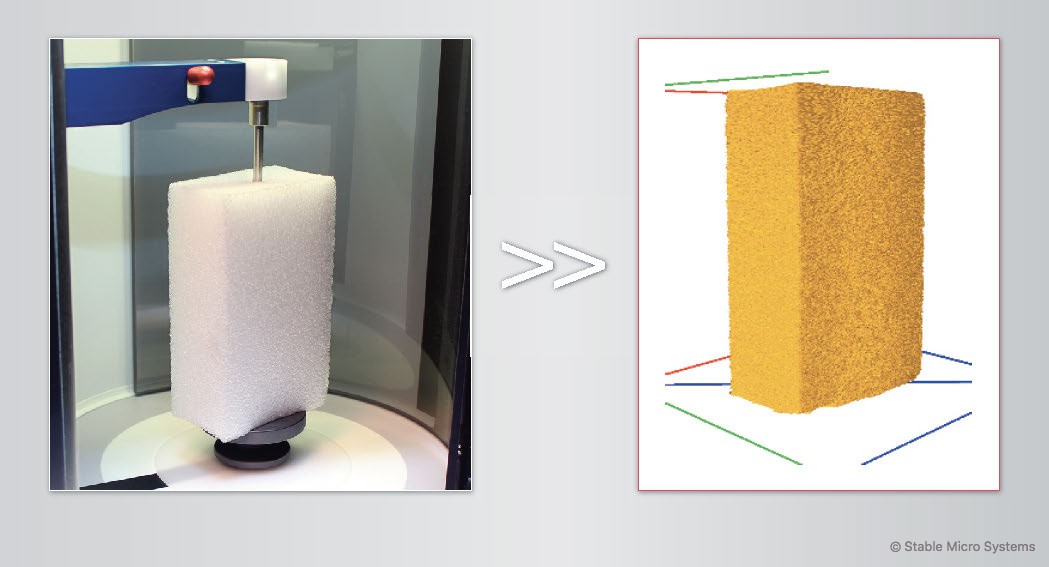

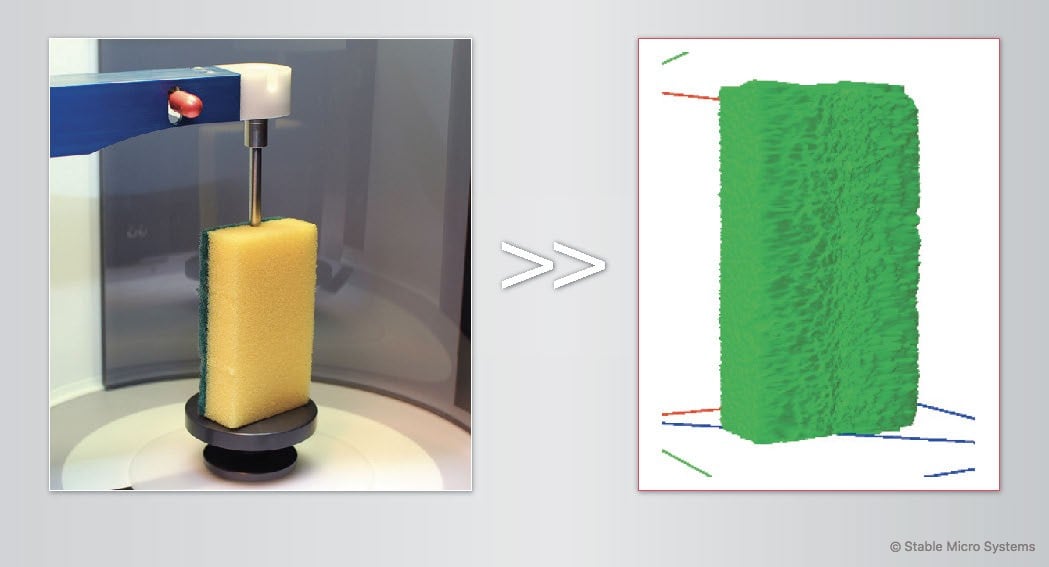

Fluid displacement techniques are not suitable for porous materials. The Volscan Profiler is a non-contact laser-based measurement that is not affected by sample porosity.

Mercury displacement techniques represent a toxic risk to the environment and are therefore illegal in many countries. The Volscan Profiler has been verified as accurate as mercury displacement methods.

Gas displacement techniques usually measure very small samples or otherwise attract a high instrument price. The Volscan Profiler has the largest measurement envelope in its class.

X-ray techniques are expensive and present a health and safety issue and therefore require fully trained operators. The Volscan Profiler uses an eye-safe laser and therefore is the safest procedure for density determination.

If you’ve designed a product in a CAD package and then you 3D print it, one concern will be whether what has been printed is what you designed. In many cases you’ll need your printed object to be dimensionally accurate and iterations of printing your design are almost inevitable to adjust the printing settings to obtain a product that is dimensionally accurate. And you’ll need a means of quickly and accurately measuring these dimensions.

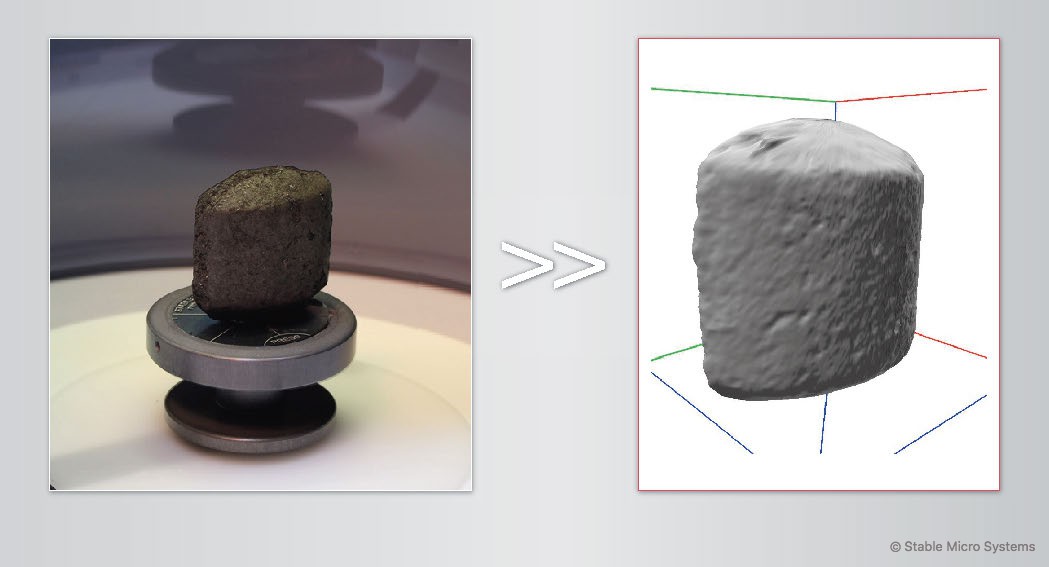

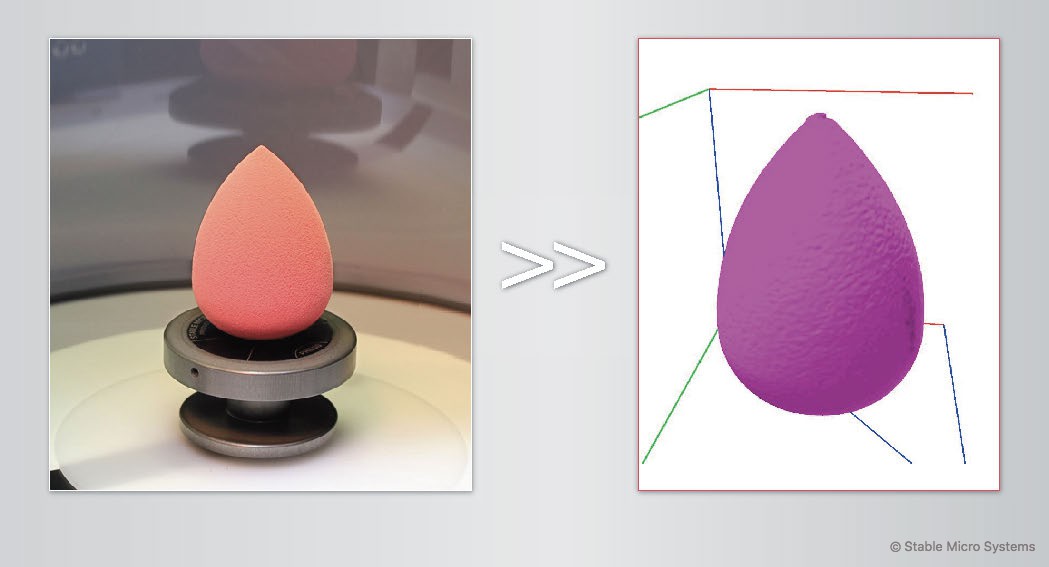

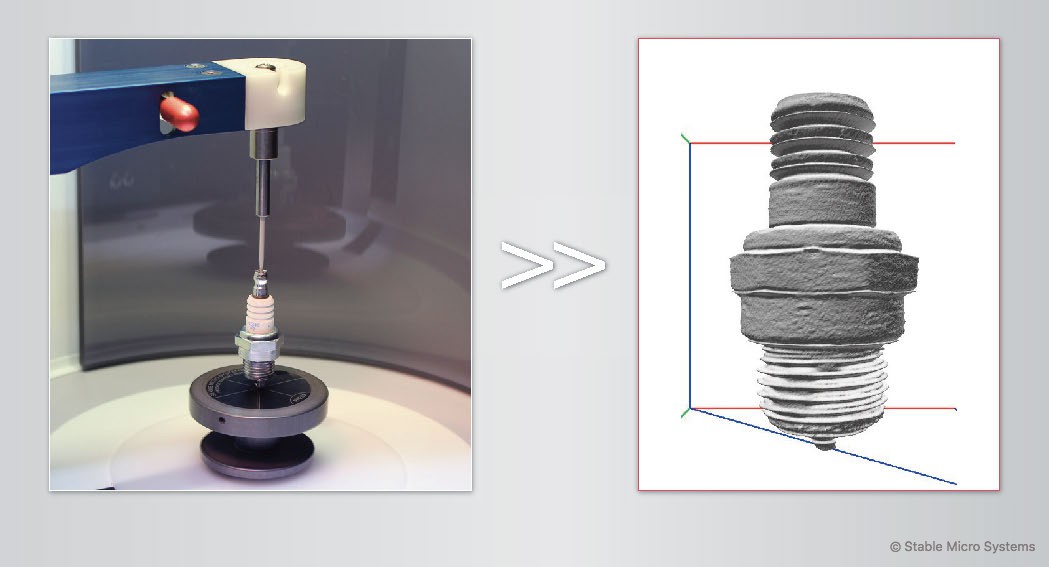

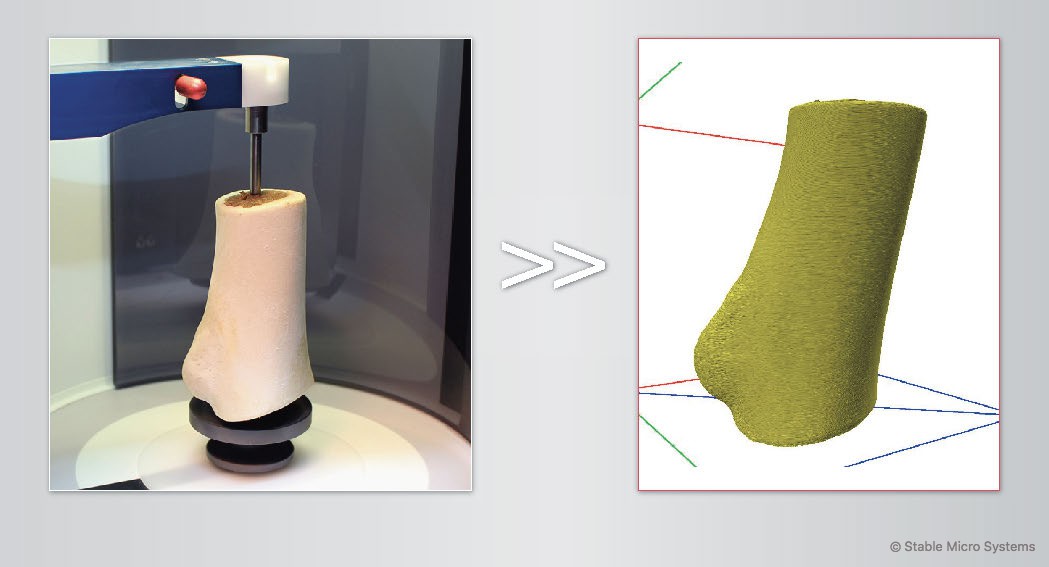

Why settle for a measurement technique that gives only one value? The Volscan Profiler gives the most comprehensive set of dimension-based parameters available, that can be visually shown in 2D and 3D and then digitally archived for future retrieval in a variety of data formats.

1

1 2

2 3

3 4

4 5

5 6

6 7

7 8

8