Measuring the Volume, Density and Dimensions of Food Products

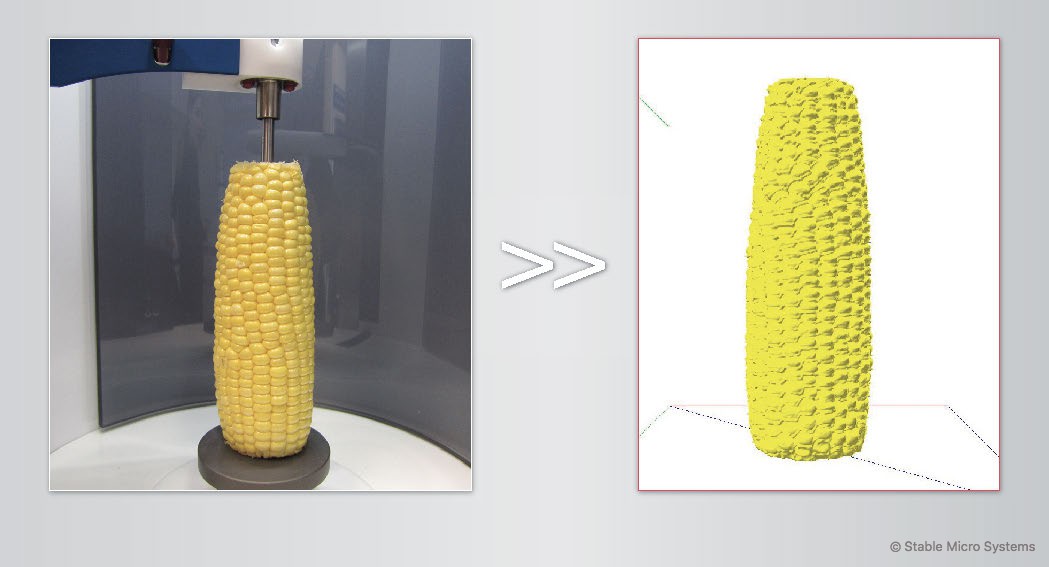

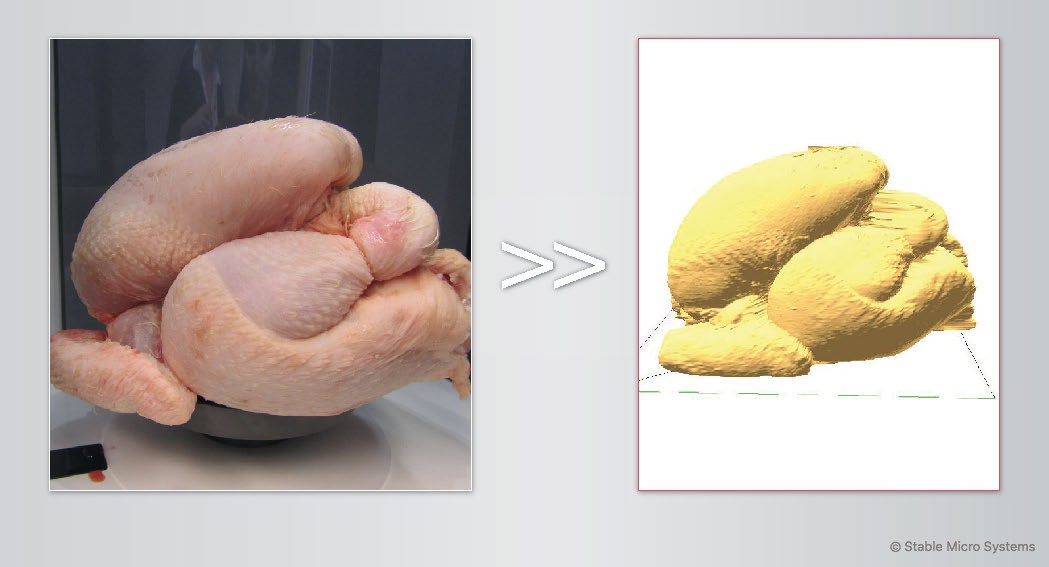

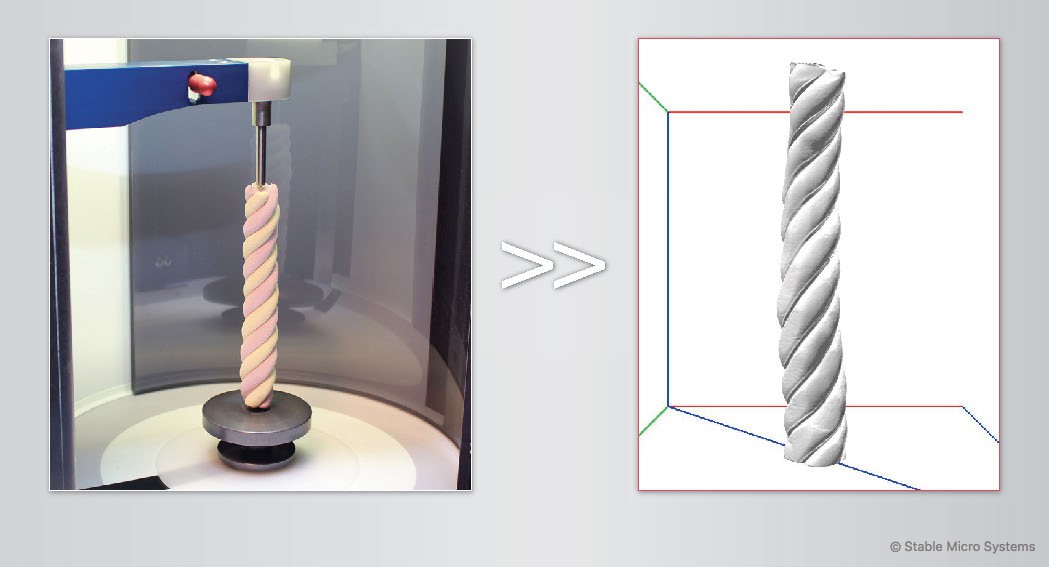

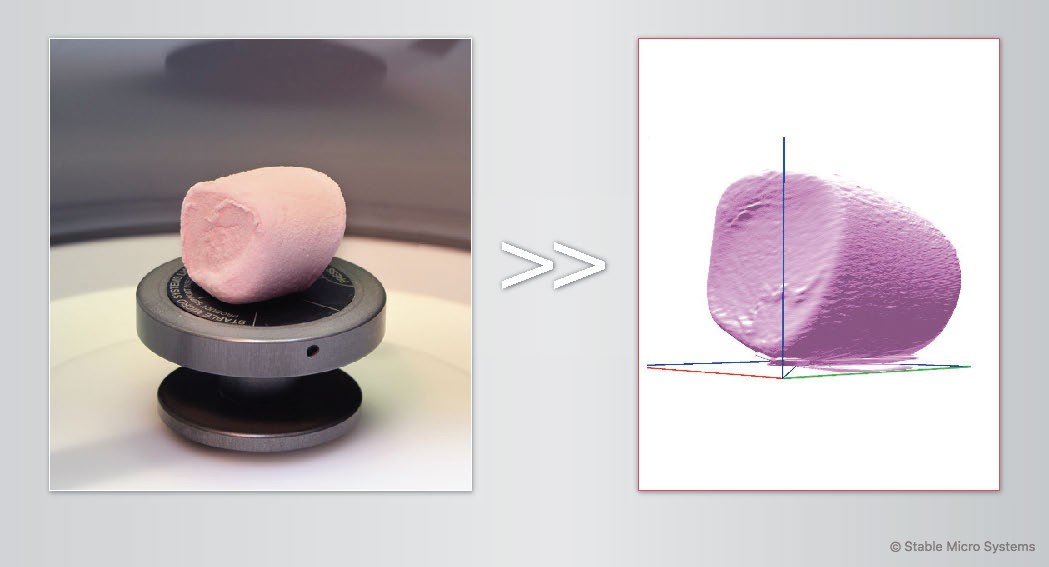

The Volscan Profiler can measure a wide range of dimensionally based parameters.

Why measure Volume, Density and Product Dimensions using a Volscan Profiler?

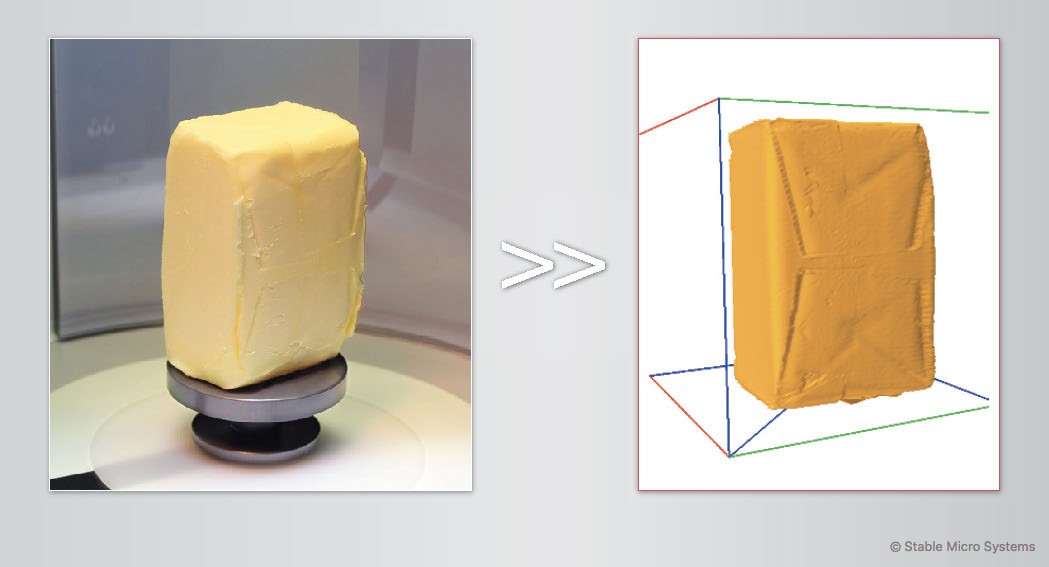

Not only is Volume critical to bakery products, but it is also an important physical property of agricultural products, meats and packaging.

Agricultural products have the characteristic of being ‘low value added’ when compared with other industrial commodities. As a result, the application of state-of-the-art technology to the agricultural sector has been slow; it is only in relatively recent times that various up-to-date techniques have reached the point of practical implementation.

Previous volume methods may have involved simple water displacement; however, this method produces one volume value which is usually manually recorded and thereby attracts operator inaccuracy with no data archiving system for future retrieval. Fluid displacement techniques are also unsuitable for porous materials.

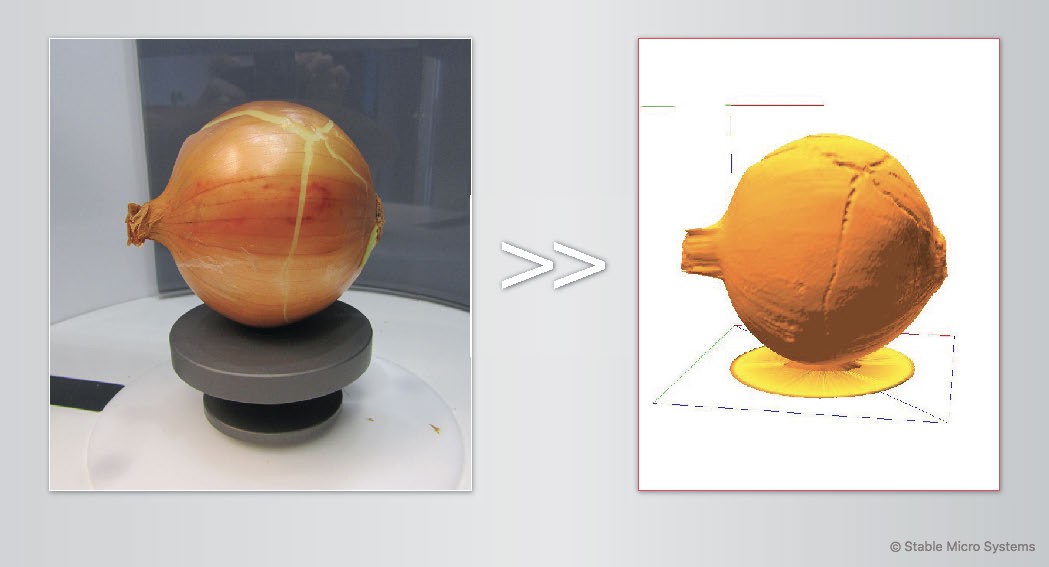

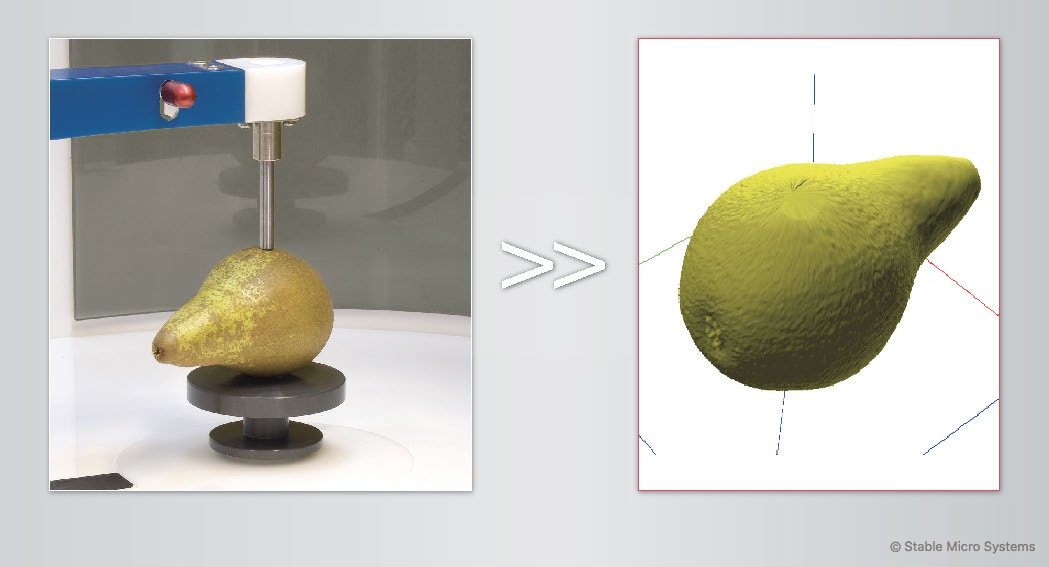

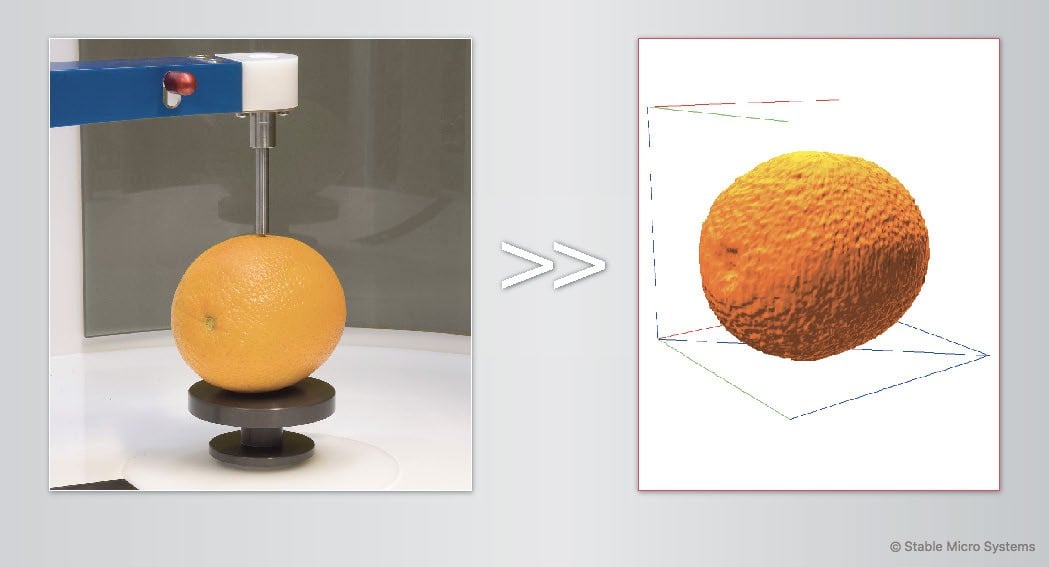

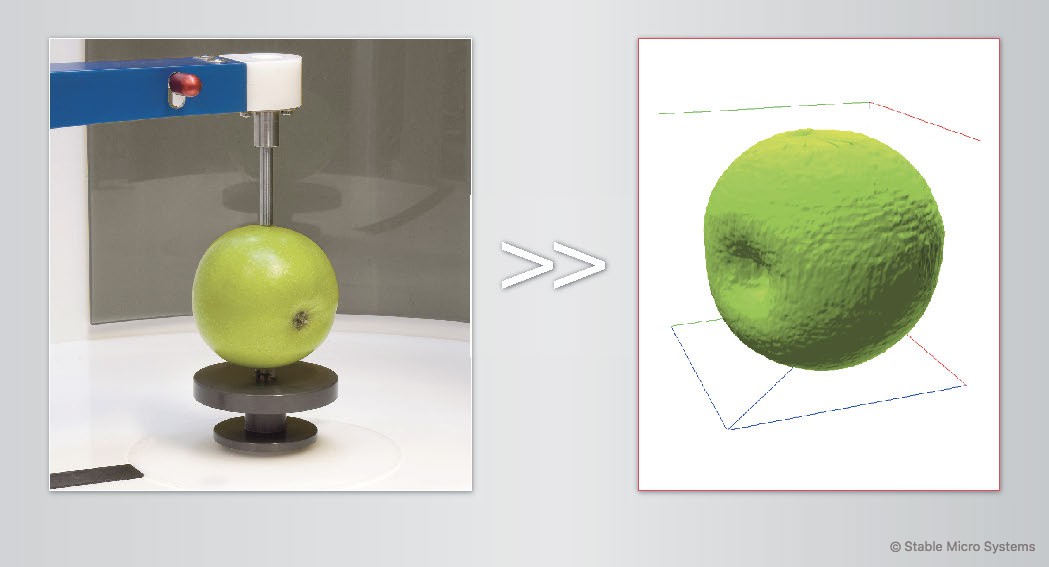

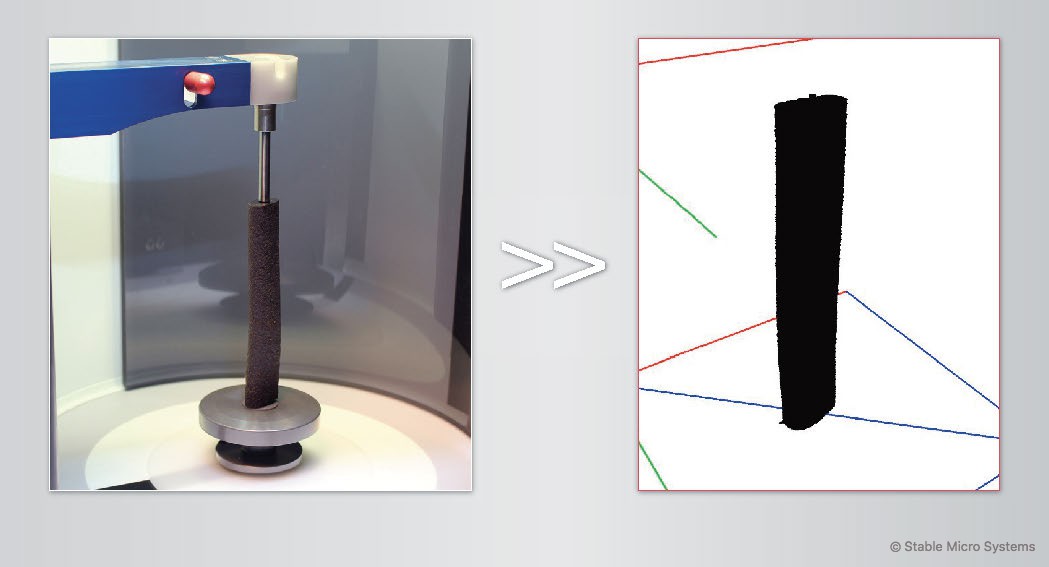

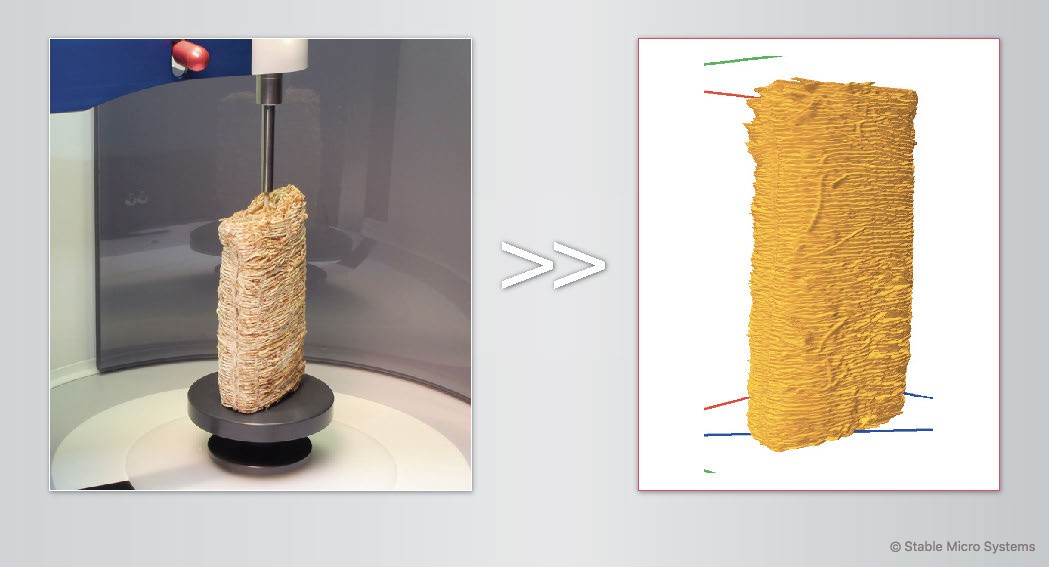

The Volscan Profiler is a non-contact laser-based measurement that is not affected by sample porosity. It can also measure so much more than a single Volume number, giving you valuable information to help you bring more dimensionally controlled products to the market whatever the test sample.

Recent new applications of the Volscan Profiler fall into the fish, fruit and snack industries where volume and dimensions are now quickly measured. Examples of use include:

The impacts of vacuum microwave drying on osmosis dehydration of tilapia fillets

Antioxidant profile of thinned young and ripe fruits of Chinese peach and nectarine varieties

In addition, the USDA and other scientists in the Egg Industry are finding the Volscan Profiler useful for the measurement of egg shape and dimensions which has been notoriously difficult in the past by other means.

The smooth surface and ovoid shape of an egg shell makes using micrometers to determine shape index difficult. Placement of micrometers varies by each individual. Historically, determining the specific density of an egg has required the egg be placed in saline solutions of known concentrations to assess at which concentration the egg ‘floats’. Again, this measurement required the visual perception of when an egg is ‘floating’. Objective determination of egg shape, volume, and density can be found in one minute per egg using the Volscan Profiler. Measurements include egg length, maximum width, shape index and length at maximum width, producing a 3D image of the egg. Repeated measurement of the same egg produces less than 1% variability in measured outcomes. The egg shape and volume information from this device can be utilised by poultry breeders, producers, and processors, as well as, housing and processing equipment and egg carton manufacturers.

Examples of use include:

Evaluation of current and emerging techniques for measuring eggshell integrity of the domestic fowl

Assessing the shape of the avian egg

Why measure one value when within the same time the Volscan Profiler can provide you with an additional 24 automatic measurements?

1

1 2

2 3

3 4

4 5

5 6

6 7

7 8

8 9

9 10

10 11

11