Measure the texture of dairy products

Learn about the many ways a Texture Analyser can be used to determine the texture of your dairy products.

Why measure the texture of dairy products?

In the dairy product sector, texture measurement takes on a pivotal role, driven by an increasingly discerning consumer base and expanding product variety found on supermarket shelves. From creamier yoghurt to stretchier mozzarella and softer scooping ice cream, consumers have come to expect specific sensory profiles for each dairy item.

Research has shown that the texture of dairy products is intimately linked to their popularity, with attributes like softness or hardness significantly impacting brand loyalty and overall satisfaction.

Manufacturers face challenges related to structural changes during unit operations and formulation adjustments, which can introduce batch-to-batch variations in products, from yoghurt separation to cheese crumbliness.

To address these concerns and ensure consistently high-quality offerings, quantifiable texture analysis plays a critical role. It allows manufacturers to monitor and measure the sensory properties and functionality of dairy products, offering both the assurance that their products meet consumer expectations and the practicality necessary for successful production and packaging.

How a Texture Analyser can be applied to dairy product texture measurement?

Dairy products, ranging from milk and yogurt to cheese and ice cream, inherently possess distinct textural attributes that significantly contribute to consumer enjoyment and preference. Incorporating a Texture Analyser into the manufacturing and development processes of these products offers a wide range of advantages:

- Texture profiling: From the creaminess of yoghurts to the spreadability of soft cheeses and the scoopability of ice cream, dairy products have unique texture expectations. A Texture Analyser provides precise metrics to categorise and maintain these profiles.

- Optimising formulations: Ingredients, cultures, thickeners and additives in dairy can change the final texture. The Texture Analyser assists in adjusting formulations to achieve the desired mouthfeel and consistency.

- Effect of processing: Investigate how various processing techniques, like pasteurisation, fermentation, or homogenisation, affect the texture of dairy products.

- Quality assurance and control: Ensuring consistency across batches is vital. Texture testing ensures every product aligns with brand quality standards, fostering consumer trust and loyalty.

- Shelf life and storage condition insights: Dairy products can undergo textural changes with time or temperature changes like free-thaw cycles, such as yoghurts becoming watery or cheeses hardening. Texture analysis offers insights into shelf life and ways to optimise it.

- Ingredient substitution: When replacing traditional dairy ingredients with alternatives, a Texture Analyser ensures that the new formulation maintains the desired texture. With the rise of lactose-free or vegan dairy alternatives, understanding their textural implications compared to traditional dairy is crucial.

- Sensory analysis correlation: By combining data from the Texture Analyser with sensory evaluations, researchers can draw insights into consumer texture preferences.

- Competitor comparisons: Dairy businesses can compare the texture of their products to those of competitors to identify market differentiators or areas for improvement.

- Claims substantiation: If a product is marketed with specific texture claims, like "creamy" or "thick," the Texture Analyser offers empirical evidence to support these claims.

By integrating the insights from a Texture Analyser with innovative ingredients and product ideas, dairy businesses can optimise product quality, meet evolving consumer preferences, and maintain a competitive edge in the market.

Typical measurements

Dairy products encompass a wide range of textures, from the creaminess of yoghurts to the firmness of hard cheeses.

Here are the key texture properties that a Texture Analyser can measure for dairy items:

Consistency

Critical for semi-solid dairy products such as yoghurt, cream, mayonnaise or mousses. It quantifies the product's resistance to flow.

Adhesiveness/stickiness

Measures the work needed to pull a dairy product away from a surface, which is pertinent to products like cream cheese or thick yoghurts.

Springiness/elasticity

Evaluates how quickly a product returns to its original shape after deformation. This can be vital for products like mousses or certain soft cheeses.

Gel strength

Important for gelled dairy products such as panna cotta, custard, or set yoghurts. It measures the force required to break the gel structure.

Gel strength

For alternative proteins that utilise gelling agents or undergo gel-forming processes, understanding the strength and stability of these gels can be essential.

Bite/cutting strength

Pertinent to hard cheeses, this evaluates the force required to cut through the product.

Squeeze flow characteristics

Assesses the flow behaviour of cheese when subjected to compression.

Work softening

Fats or shortenings become softer and more pliable as they are subjected to mechanical work, such as mixing, kneading, or shearing which can be mimicked by repeated extrusion cycling.

Firmness

Important for cheeses, butter, frozen yoghurts and ice cream, this measures the force required to compress the product.

Cohesiveness

Assesses how well a product retains its structure when subjected to stress. Relevant for yoghurts, cheeses, and dairy desserts.

Spreadability

Especially relevant for products like butter or cheese spreads, this measures the product's ability to spread smoothly without difficulty.

Extensibility/stretchability

A crucial parameter for products like processed cheese meant for melting on burgers or pizzas.

Fracturability

Measures the point at which certain hard cheeses or frozen dairy products might break or fracture.

Flexibility

Measuring the flexibility of cheese involves evaluating its ability to bend, deform, or stretch when subjected to mechanical stress.

Foam stability

Involves evaluating how well e.g. whipped cream maintains its foam structure over time by applying a light force to its surface and tracking the foam disintegration.

Shell strength

Measuring the shell strength of eggs involves evaluating the ability of the eggshell to withstand external forces without breaking or cracking.

Utilising a Texture Analyser allows dairy manufacturers to capture objective, repeatable measurements of these textural attributes, facilitating product optimisation, ensuring consistent quality, and meeting consumer expectations.

Typical product test and graph

Case studies

Whether its providing the solution for General Mills to file a patent for their cheese compositions, allowing Dupont Nutrition Biosciences to measure the firmness of their high acyl gellan whipping cream, giving a means of assessing 3D printability of soft cheese to the Indian Institute of Technology or offering a method for Yoplait to measure their non-dairy fermented food product, a Texture Analyser is adaptable and flexible in its application to measure the bespoke texture of your product and then enable its quality to be controlled in your manufacturing to guarantee consistency and customer satisfaction.

With deep expertise in dairy product texture analysis, we’re well equipped to support innovation in the dairy sector – just ask our customers.

Probes and attachments for measuring the texture of dairy products

A wide range of probes and attachments an be integrated with our instruments, allowing testing to be precisely adapted to the material or product under evaluation. Applications include back extrusion tests to compare yoghurt consistency, cutting tests to assess cheese firmness or a spreadability rig to measure spread properties.

Over the years, we have collaborated with leading scientists and organisations across diverse industries to design and refine attachments that meet highly specific testing requirements. When a suitable solution does not already exist, we develop one – such as the Cheese Extensibility Rig, a Community Registered Design that exemplifies our commitment to innovation in solving complex testing challenges.

The examples provided illustrate a selection of specialised attachments and commonly performed measurements within this application area. This list is not exhaustive; a wide range of additional options are available for the testing of dairy products. All instruments in the Texture Analyser range can be used to perform the tests described.

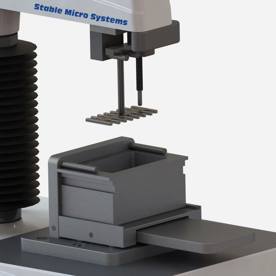

Back Extrusion Rig

Used to assess the consistency or extrudability of such products as yoghurt, sauces, cream.

Forward Extrusion Rig

Allows consistency assessment by simulating the force required to extrude the sample through an orifice by a consumer.

Spreadability Rig

Used for the measurement of spreadability of fats, table spreads.

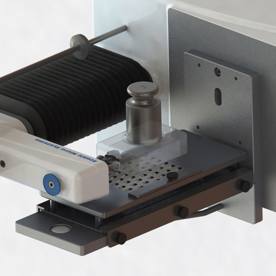

Egg Quality Testing System

This enables the producer to monitor a range of parameters to ensure that eggs meet the required quality standards.

Wire Cutter

Used to assess firmness of block forms of butter, margarine, cheese with the aid of a fine wire.

Fracture Wedge Set

Can be used to assess fracture/‘bite force’ of hard cheeses.

Cylinder Probes

Can be used in a similar manner as a backward extrusion rig for e.g. mayonnaise, yoghurt consistency determination.

Spherical Probes

To apply small deformation to samples like cheese to determine firmness.

Conical Probes

Traditionally used in penetrometry type tests.

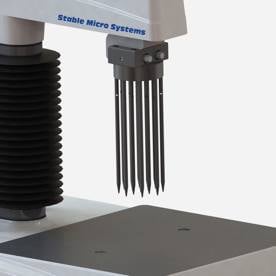

Multiple Puncture Probe

Particularly suited for the penetration of multiple particulates or non-uniform products to create an averaging effect.

Cheese Extensibility Rig

Allows the assessment of molten cheese by utilisation of a vessel and fork design.

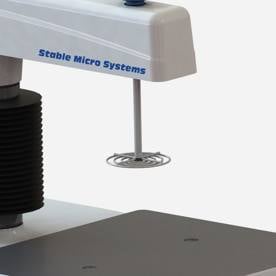

Cream Probe

Allows measurement of food foam firmness according to standard DLG method.

Grating Rig

Used to measure the ease of grating of all types of hard cheese.

Universal Peel Rig

Allows measurement of the peel strength of containers up to 95mm diameter and 120mm height at three angles.

Ice Cream Scoop Rig

Measures the scooping force of soft ice creams in block form.

Universal Sample Clamp

Allows complete penetration and withdrawal of the sample whilst avoiding sample slippage, movement or lifting.

Test methods

Exponent Connect software includes a comprehensive range of test methods for dairy products, all instantly accessible at the click of a button. We streamline your texture testing process, ensuring faster access to methods and ready-to-use analysis files for your product properties.

Using the Texture Analyser for new dairy ingredient and product ideas

The dairy industry has witnessed a surge in innovation over recent years due to shifting consumer preferences, dietary needs, sustainability concerns, and technological advancements. Here are some of the newer ingredient and product ideas in dairy product research, development, and production and a typical academic reference to show how the Texture Analyser has already being applied:

Plant-based dairy alternatives

With increasing lactose intolerance and dietary preferences, there's a rise in plant-based dairy alternatives like almond, oat, soy, cashew, coconut, hemp, and pea milks and proteins and plant-based alternatives to cheese.

High protein products

Greek yoghurt, Icelandic skyr, and protein-fortified dairy drinks cater to health and fitness-conscious consumers.

A2 milk

Dairy products made specifically from cows producing A2 protein, believed to be easier to digest for some people.

Dairy snacks

Portable dairy snacks, like cheese sticks or yoghurt pouches, suitable for on-the-go consumption.

Flavoured dairy products

Exotic and novel flavours, like lavender, matcha, or rose, being introduced in yoghurts, ice creams, and milk drinks.

Functional dairy products

Probiotic-rich yoghurts, kefirs, and fermented milk products that promote gut health are becoming popular.

Low or reduced sugar products

As health concerns around sugar consumption grow, there's a push towards dairy products with reduced sugar or natural sweeteners like stevia and monk fruit.

Lactose-free products

Lactose-free milk, yoghurt, and cheese products for lactose-intolerant consumers.

Sustainability

Grass-fed, organic, and non-GMO dairy products appeal to consumers concerned about animal welfare and the environment.

Probiotic-enhanced yoghurts and drinks

Dairy products fortified with vitamins, minerals, and Omega-3.