Learn about the different ways a Texture Analyser can be utilised to measure the physical properties of adhesives and adhesive products.

The measurement of mechanical properties in adhesives and adhesive tapes represents a pivotal scientific pursuit, particularly vital within industries such as pharmaceuticals, food, medical, and packaging.

Adhesiveness, often synonymous with 'stickiness' or 'tackiness' in consumer perception, stands as a linchpin in determining the quality, performance, and effectiveness of various products like sealing tapes, curing glues, resins, waxes, adhesive plasters, and labels. Multiple factors, including temperature, moisture levels, and repeated usage, can significantly influence adhesion.

Manufacturers, aiming to align adhesive performance with functional and consumer requirements, rely on precise measurements to identify the optimal adhesive composition. The adoption of a measurement principle is essential for monitoring adhesive properties during development and quality control stages, enabling the discernment of subtle distinctions between different formulas, materials, chemical ingredients, and manufacturing processes.

These measurements facilitate batch conformity verification, comparisons of consistency between batches, shifts, and different manufacturing facilities, and are aided by the versatility of a Texture Analyser, which offers the means to assess a multitude of physical properties in various ways.

Texture Analysers can provide key insights into the physical properties of adhesives. Here's how they can be applied:

In essence, the use of a Texture Analyser in the adhesives and adhesive tapes sector ensures the production of high-quality, reliable, and application-specific products. It acts as a bridge between theoretical formulation and practical application, guaranteeing that the adhesive products are fit for purpose and perform as expected.

A Texture Analyser can evaluate a variety of mechanical properties for adhesives and adhesive tapes such as:

Measuring the force required to peel an adhesive from a substrate. This is crucial for understanding how well tapes and labels bond to various surfaces.

The maximum force the adhesive tape can withstand while being stretched before breaking.

Measures how much the adhesive tape can be stretched before it breaks, indicating its extensibility.

This metric evaluates the adhesive's resistance to shear forces, indicating how well it can maintain a bond when under stress. An adhesive's performance in high-stress environments can thus be forecasted.

For flexible adhesives, understanding how they deform under stress and return to their original state.

Evaluates how the adhesive deforms under constant stress over a designated time (creep) and how it returns to its original form after the stress is removed (recovery).

Determining the time an adhesive takes to achieve its final strength. This can be crucial for industrial applications.

Measures the force required to separate two surfaces that have been brought into brief contact. It's an indicator of the adhesive's initial grab or instant stick. A loop tack test determines the force needed to pull apart a looped adhesive tape, which is pressed against a standard surface.

Stringiness/legginess refers to the tendency of a material, such as an adhesive or a food product, to form long, thin strings or threads when pulled or stretched. Tailing occurs when a material leaves a residue or "tail" behind as it is dispensed or pulled away, often seen in applications like adhesive dispensing or ink printing. Relevant parameters for measurement include the force at which the material exhibits stringiness or tailing, the length of strings or tails formed, and the time it takes for them to break.

Represents the force needed to cause the adhesive layer to slide or shear, indicating its resistance to lateral forces.

Measuring the internal strength of the adhesive, or its ability to resist being pulled apart.

Texture analysers can give an idea about the flow and spread of adhesives under certain conditions.

Useful for hot melt adhesives or other formulations that may have a solid state.

Quantified as the force required to push a material through a specified orifice or nozzle at a controlled rate.

Accurate measurement of these properties helps manufacturers optimise formulations, ensure consistent product quality, and make informed choices about which adhesives are best suited for specific applications.

Whether its providing the solution for TESA to measure the tack force of their tapes, allowing Samsung to measure the elongation of their electronic device adhesive films or offering a method for Korea University to develop an insect-proof starch adhesive for paper box adhesion, a Texture Analyser is adaptable and flexible in its application to measure the bespoke mechanical properties of your product and then enable its quality to be controlled in your manufacturing to guarantee consistency and customer satisfaction.

You might also like:

With deep expertise in adhesives and adhesive tape physical characterisation, we’re well equipped to support innovation in the alternative protein sector – just ask our customers.

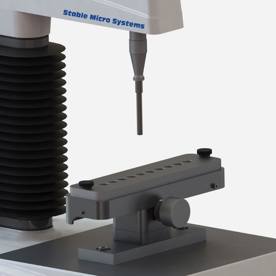

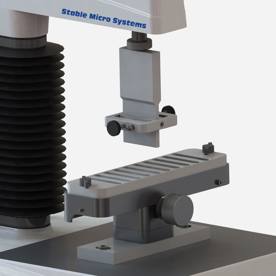

A wide range of probes and attachments can be integrated with our instruments, allowing testing to be precisely adapted to the material or product under evaluation. Applications include the Tape Unwinding Rig used to compare adhesive tape removal from the roll, loop tests to assess adhesive tape tack or adhesive tests employing a ball probe to measure a range of tape adhesive properties.

Over the years, we have collaborated with leading scientists and organisations across diverse industries to design and refine attachments that meet highly specific testing requirements. When a suitable solution does not already exist, we develop one – expanding our portfolio of Community Registered Designs and reinforcing our commitment to innovation in solving complex testing challenges.

The examples provided illustrate a selection of specialised attachments and commonly performed measurements within this application area. This list is not exhaustive; a wide range of additional options are available for the testing of adhesive products. All instruments in the Texture Analyser range can be used to perform the tests described.

Exponent Connect software includes a comprehensive range of test methods for adhesives and adhesive tapes (including ASTM, ISO, FINAT, AFERA and PSTC Standards) to provide detailed analysis of the compressive and tensile stress-strain behaviour of the adhesive product. These are all instantly accessible at the click of a button. We streamline your physical testing process, ensuring faster access to methods and ready-to-use analysis files for your product properties.

Adhesives play a pivotal role in various industries, including construction, automotive, packaging, and electronics. Research and development in this field often focus on improving performance characteristics, environmental sustainability, and safety. Here are some of the newer ingredient and product ideas in adhesive research, development, and production and a typical academic reference to show how the Texture Analyser has already being applied:

Made from renewable resources, such as plant-based polymers or proteins, these aim to reduce the carbon footprint and dependency on petroleum-based ingredients.

Advanced adhesives that don't require heat, water, or pressure to bond, useful in labels, tapes, and other applications.

Designed to enable easier recycling of products by allowing for the adhesive to be separated from substrates.

Inspired by natural systems, these adhesives can "heal" or revert to their original state after being damaged.

Adhesives that can be easily removed or repositioned without leaving residue or damaging surfaces, useful in applications like labels or temporary fixtures.

Adhesives designed for medical applications like wound care, medical device attachment, or drug delivery, with biocompatible and often bioresorbable properties.

Incorporation of nanoparticles to improve adhesive properties such as toughness, thermal stability, or electrical conductivity.

Formulations suitable for 3D printing technologies, allowing for custom adhesive structures or patterns.

They're solid at room temperature but melt when heated, allowing for quick setting and bonding.

These formulations replace solvents with water, reducing VOC emissions and improving workplace safety.

These formulations undergo chemical reactions (often involving moisture or UV light) to bond surfaces. Adhesives that can change properties in response to external stimuli, such as temperature, light, or pH.

Designed to conduct or insulate heat in applications like electronic devices.

Adhesives formulated to be eco-friendly, reducing VOC emissions, and with degradable or recyclable properties.

Adhesives capable of bonding dissimilar materials like metals and composites with high durability and resistance to environmental factors.

Adhesives that harden or set when exposed to UV light, offering fast curing times and reduced energy consumption.

Formulations designed to withstand extreme temperatures, pressures, or aggressive chemicals, suitable for aerospace, deep-sea, or heavy industrial applications.

Infused with conductive materials like silver or carbon, these are used in electronic assemblies and devices.